Beauty Lounge Neuburg - Fett-weg-Spritze ‼️‼️bei Beauty Lounge Neuburg . Injektionslipolyse Kinn und Bäckchen ☎️08431/399 48 53 Wir freuen uns auf Sie!! | Facebook

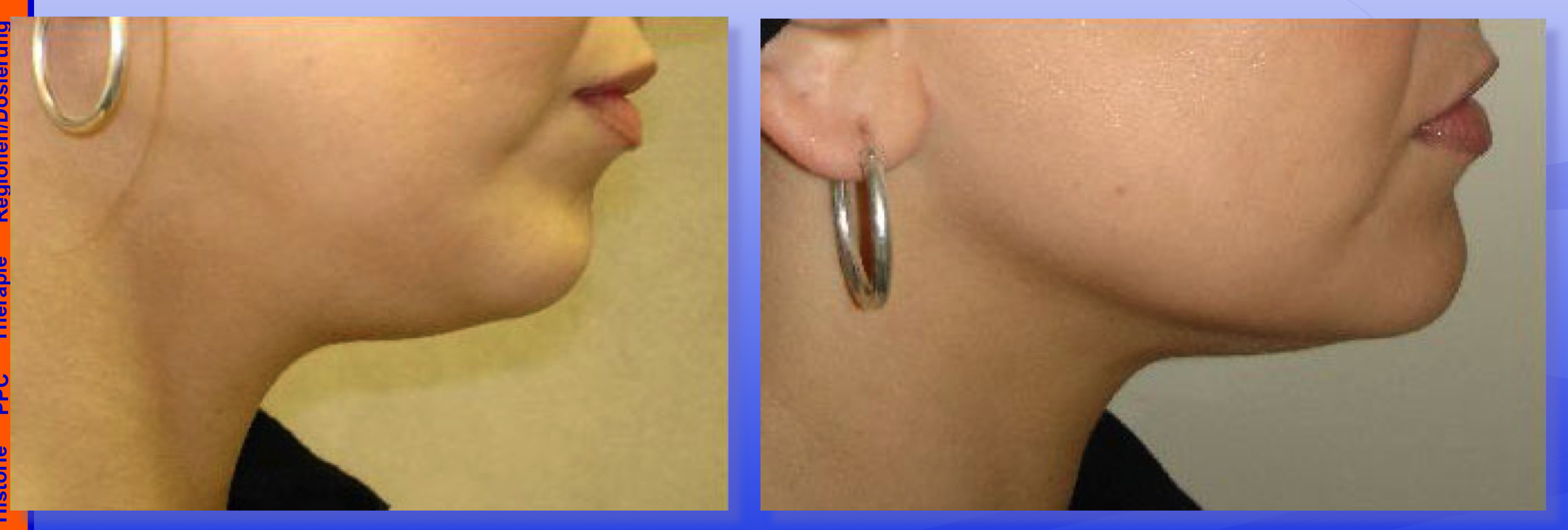

Beauty Lounge Neuburg - Lipolyse ( Fett-Weg-Spritze) Das tolle Ergebnis nach nur einer Sitzung ‼️ . Jetzt Termin vereinbaren ☎️08431/399 48 53 . Wir freuen uns auf Sie | Facebook

Fett weg Spritze Kinn 4. Behandlung! Lipolyse Kinn Vorher Nacher Kinn| Nina Nice – Hyaluron Unterpritzung